Manufacturing Productivity Supports The Reshoring Trend

Reshoring will become a dominant trend in US manufacturing. This transition will strain existing machine, supply chain and labor bottlenecks, and necessitate the need for manufacturers to “do more with less”, and upgrade their manufacturing productivity.

Companies that successfully execute this transformation, will leapfrog their competitors, and reap the benefits of lower transportation costs, shorter lead times, and more effective JIT inventory management.

Reshoring strengthens the U.S. economy, reduces budgetary & trade deficits, builds a skilled work force and restores communities. It also benefits companies, because shorter supply chains increase speed and agility, and help to better service customers who demand solutions which cannot be met by globe spanning supply chains.

This shifts the paradigm from “off shoring is cheaper” to “local can reduce total cost of ownership”.

Beginning under President Trump, and continuing with the current administration, the US Government has prioritized reshoring as a policy imperative, particularly (but not only), for critical industries. This sea change in US trade and industrial policy is beginning to bear fruit, as evidenced by the following:

- Jobs in the medical equipment manufacturing industry were up 400% in 2020 vs 2021, with the upward trend continuing into 2021.

- Intel, TSMC, Samsung and Texas Instruments have all announced massive US semiconductor manufacturing investments.

- US reshoring jobs created in 2020 outpaced those by direct foreign investment for the first time since 2013.

Factory Productivity Shortcomings Are Obstacles

The obstacles faced by companies working to reshore their supply chains can be broadly placed into two buckets, 1) governmental, and 2) commercial. Other than coordinated political activism, there is little that businesses can do about the former, but there is plenty that they can do about the latter.

Within the commercial bucket, reshoring companies will need to manage a tight labor market, machine, supply chain and labor bottlenecks, plus offset higher average labor costs (partially accomplished by the relatively low cost of US energy). This means that companies must learn how to do more with less, faster; in other words, they need to become LEAN.

LEAN Manufacturing Is The Solution

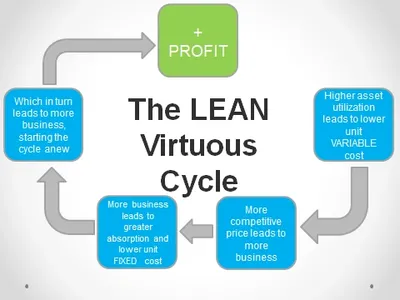

LEAN Continuous Improvement is the process with which reshoring companies can break their production constraints, while shortening lead times, and is perhaps the single biggest profit driving initiative that a typical manufacturing organization can undertake. For companies dealing with capacity, labor and supply bottlenecks, breaking those bottlenecks becomes an imperative, and a strong LEAN consulting partner accelerates that transformation. Most companies possess significant latent manufacturing capacity, the unleashing of which results in a “LEAN Virtuous Cycle” of lower operating costs, leading to more business, which in turn leads to lower operating costs. This, combined with a relentless application of LEAN and Six Sigma tools to drive out the “7 Wastes”, can launch profits to previously unattained levels.

Companies that learn how to break bottlenecks, reduce cycle times, minimize material wastes, optimize line speeds, cut downtime, plan strategically and analytically solve problems will win in internationally competitive businesses. Those that do not, will not survive.

What are your thoughts? Comment below.

ANCONATEK Inc. provides manufacturing productivity consulting services to the food, beverage, CPG and other high volume manufacturing industries. To learn more about how we can help make your manufacturing operations highly productive, cost effective, and more profitable, click here for my full contact information, or call Bruno Padovani today at 630-881-0331. We would love to work with your company to help you win in the international manufacturing arena.

6 Comments

Scott Sargis January 31, 2022 at 5:10 pm

I agree that LEAN Continuous Improvement is the process with which reshoring companies can break their production bottlenecks. Additionally, Lean Six Sigma consultants like yourself are the key to breaking bottlenecks, reducing cycle times, minimizing material wastes, optimizinge line speeds, cutting downtime, planning strategically and analytically solving problems, to will win in internationally competitive businesses.

就爱要 June 14, 2022 at 4:03 pm

Where there is a will, there is a way.

anconatek.com June 20, 2022 at 12:23 am

So true!

Twicsy July 2, 2022 at 5:13 pm

Great post.

anconatek.com July 29, 2022 at 9:21 pm

Thank you for your comment, sir. I’d be happy to share notes with you, or assist you with your company’s manufacturing productivity needs. Sincerely,

Bruno Padovani Cell: +1 630-881-0331

EdwardGen July 13, 2023 at 4:30 pm

Thanks for the post

_________________

ойын автоматын 82593